NASA is preparing space at the agency’s Kennedy Space Center in Florida for upcoming assembly activities of the SLS (Space Launch System) rocket core stage for future Artemis missions, beginning with Artemis III.

Teams are currently outfitting the assembly building’s High Bay 2 for future vertical assembly of the rocket stage that will help power NASA’s Artemis campaign to the Moon. During Apollo, High Bay 2, one of four high bays inside the Vehicle Assembly Building, was used to stack the Saturn V rocket. During the Space Shuttle Program, the high bay was used for external tank checkout and storage and as a contingency storage area for the shuttle.

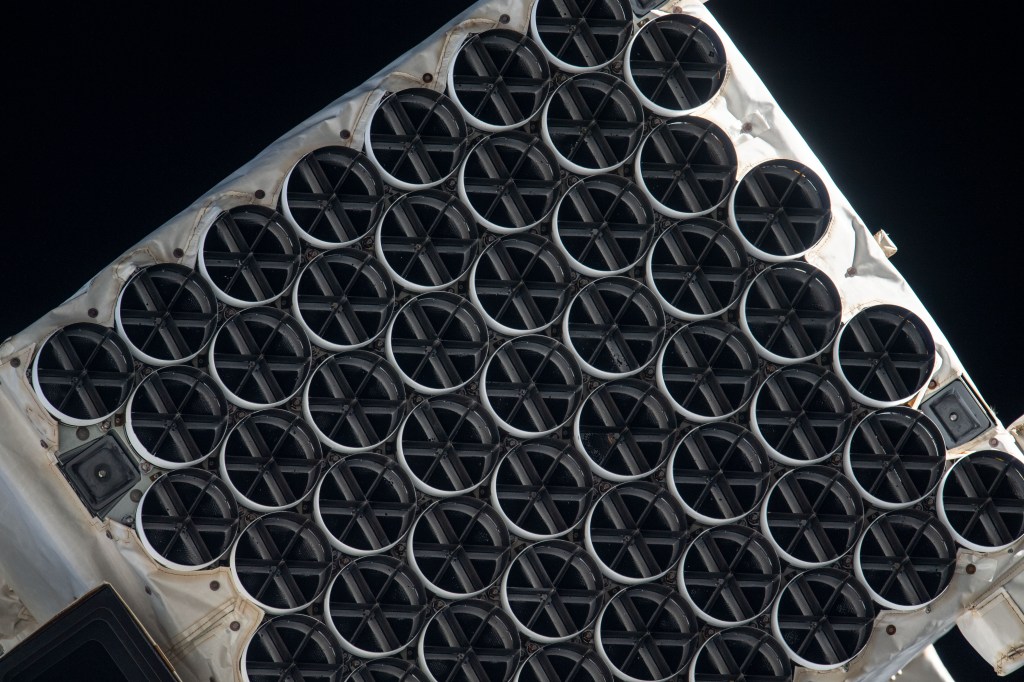

Michigan-based Futuramic is constructing the tooling that will hold the core stage in a vertical position, allowing NASA and Boeing, the SLS core stage lead contractor, to integrate the SLS rocket’s engine section and four RS-25 engines to finish assembly of the rocket stage. Vertical integration will streamline final production efforts, offering technicians 360-degree access to the stage both internally and externally.

“The High Bay 2 area at NASA Kennedy is critical for work as SLS transitions from a developmental to operational model,” said Chad Bryant, deputy manager of the SLS Stages Office. “While teams are stacking and preparing the SLS rocket for launch of one Artemis mission, the SLS core stage for another Artemis mission will be taking shape just across the aisleway.”

Under the new assembly model beginning with Artemis III, all the major structures for the SLS core stage will continue to be fully produced and manufactured at NASA’s Michoud Assembly Facility in New Orleans. Upon completion of manufacturing and thermal protection system application, the engine section will be shipped to NASA Kennedy for final outfitting. Later, the top sections of the core stage – the forward skirt, intertank, liquid oxygen tank, and liquid hydrogen tank – will be outfitted and joined at NASA Michoud and shipped to NASA Kennedy for final assembly.

The fully assembled core stage for Artemis II arrived at Kennedy on July 23. NASA’s Pegasus barge delivered the SLS engine section for Artemis III to Kennedy in December 2022. Teams at NASA Michoud are outfitting the remaining core stage elements and preparing to horizontally join them. The four RS-25 engines for the Artemis III mission are complete at NASA’s Stennis Space Center in Bay St. Louis, Mississippi, and will be transported to NASA Kennedy in 2025. Major core stage and exploration upper stage structures are in work at NASA Michoud for Artemis IV and beyond.

NASA is working to land the first woman, first person of color, and its first international partner astronaut on the Moon under Artemis. SLS is part of NASA’s backbone for deep space exploration, along with the Orion spacecraft, supporting ground systems, advanced spacesuits and rovers, the Gateway in orbit around the Moon, and commercial human landing systems. SLS is the only rocket that can send Orion, astronauts, and supplies to the Moon in a single launch.

News Media Contact

Jonathan Deal

Marshall Space Flight Center

Huntsville, Ala.

256-544-0034