Professional Documents

Culture Documents

750 GPM - 205 PSI - Dimensiones Bomba 5-1823AF y Motor Clarke JU6H-UF54

750 GPM - 205 PSI - Dimensiones Bomba 5-1823AF y Motor Clarke JU6H-UF54

Uploaded by

Carlos_MKTRCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

750 GPM - 205 PSI - Dimensiones Bomba 5-1823AF y Motor Clarke JU6H-UF54

750 GPM - 205 PSI - Dimensiones Bomba 5-1823AF y Motor Clarke JU6H-UF54

Uploaded by

Carlos_MKTRCopyright:

Available Formats

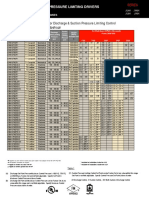

Section 913 Page 214 FAIRBANKS NIJHUIS™

Date NOVEMBER 2013 MODELS 1800, 2800, 5800

SINGLE-STAGE HSC FIRE PUMPS

JU6H-UF30, UF32, UF34, UFABL8, UFABL0

UFABL2, AB76, UF50, UF52, UF54

UF58, UFD0, UFD2, UFG8, UFM0, UFM2,

UFM8, UF60, AAQ8, AARG, UF62, UF68, UF84

PUMP SIZE

CASE POWER

DISCH MODEL BORE SUCTION SERIES S W X Z CP HB HD HF1 HM HY YY

4 4"2823F 14 6 - 6-7/8 17-5/8 13 8-3/8 31-11/16 98 20 44 65-3/4 22-3/8 15-1/4

4 4"5824F 18 5 - 9-1/2 18-3/8 14 9-1/2 33-1/4 98 22 44 67-3/4 21-5/8 14

5 5"2823F 14 8 - 8-1/4 17-5/8 13-1/2 9-3/4 31-11/16 98 23 44 68-3/4 22-3/8 17-1/4

5 5"2824F 18 8 - 8-1/8 18-7/8 15 10-5/8 33-3/8 98 23 44 68-3/4 21-1/8 18-3/4

6 6"2823F 14 10 - 9-3/8 20-1/8 13-1/4 10 35-7/8 98 25 44 70-3/4 19-7/8 18

6 6"2824F 18 10 - 9-3/8 20-1/8 16 11-3/4 35-7/8 98 25 44 70-3/4 19-7/8 20

6 6"2825F 18 10 - 9-3/8 22-5/8 18 12-1/8 39-1/4 98 26 44 71-3/4 17-3/8 22

6 6"2876F 12 10 - 6-7/8 16-5/8 20-1/2 7-1/8 29-11/16 88 23 39 68-3/4 13-3/8 14

6 6"5823F 15 8 - 8-3/4 22-1/2 15-1/2 8-3/4 40-1/4 98 23 44 68-3/4 17-1/2 15

6 6"5824F 18 8 - 9-5/8 22-1/2 16 9-5/8 40-1/8 98 24 44 69-3/4 17-1/2 16

6 6"5876F 10 10 - 9 20-5/8 13 7-1/2 36-3/4 98 25 44 70-3/4 19-3/8 15

8 8"2823F 14 12 - 10-3/4 20-1/2 16 10-3/4 36-5/8 98 28 44 73-3/4 19-1/2 22

8 8"2824F 18 12 - 10-3/4 23-3/4 16 12-1/2 41-1/2 98 28 44 73-3/4 16-1/4 22

8 8"1826F 24 12 7 13-1/2 28-5/8 20 15 51-1/2 108 31 49 76-3/4 21-3/8 25

NOTES: CAUTION:

1. Flange ratings are either 125# or 250#. Reducers and/or increasers may be The driveshaft is designed to operate at a 2° angle with the input and output shafts in

required to meet NFPA Pamphlet 20, Table 2-19. parallel. The engine crankshaft is to be set with a parallel offset of “B” ± 0.10 inches

2. Not for construction, installation or application puposes unless certified. vertically above the pump shaft and 0.00"± 0.10 inch parallel offset horizontally right

Dimensions shown are typical and may vary due to various tolerances. or left of the pump shaft. Refer to the certified driveshaft instructions manual for

3. All bases are required to be completely filled with grout. alignment instructions.

4. Unit installation and final driveshaft alignment must be done by the

installing contractor.

© 2017 Pentair plc

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5836)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (862)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (351)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (268)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- AERINS 42 Inch Riding Mower-Manual PDFDocument56 pagesAERINS 42 Inch Riding Mower-Manual PDFPhilip Benton83% (6)

- Quantum Stylist 9960Document33 pagesQuantum Stylist 9960Tanga ManagementNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Transmision Allison PDFDocument1,130 pagesTransmision Allison PDFmnvijaybabu100% (3)

- NBC Two WheelerDocument36 pagesNBC Two WheelerGagan Deol100% (8)

- Park Lynch PDFDocument542 pagesPark Lynch PDFmtshNoch keine Bewertungen

- Beginner WatchmakingDocument286 pagesBeginner Watchmakingjfleython92% (12)

- Experimental Data For Model Validation of Smoke Transport in Data CentersDocument158 pagesExperimental Data For Model Validation of Smoke Transport in Data CentersCarlos_MKTRNoch keine Bewertungen

- PLD Models For Discharge & Suction Pressure Limiting Control G G Fm-Ul-Cul Approved Ratings BHP/KWDocument6 pagesPLD Models For Discharge & Suction Pressure Limiting Control G G Fm-Ul-Cul Approved Ratings BHP/KWCarlos_MKTRNoch keine Bewertungen

- Almacen Floxocorte 4 Rack Menos CriticoDocument9 pagesAlmacen Floxocorte 4 Rack Menos CriticoCarlos_MKTRNoch keine Bewertungen

- FM Global Property Loss Prevention Data Sheets: Fire Protection System Inspection, Testing and MaintenanceDocument67 pagesFM Global Property Loss Prevention Data Sheets: Fire Protection System Inspection, Testing and MaintenanceCarlos_MKTRNoch keine Bewertungen

- Electrobomba Jockey PVM 1-19 - 3HPDocument5 pagesElectrobomba Jockey PVM 1-19 - 3HPCarlos_MKTRNoch keine Bewertungen

- Fairbanks Nijhuis MODEL 1800: Section Date OCTOBER 2017Document1 pageFairbanks Nijhuis MODEL 1800: Section Date OCTOBER 2017Carlos_MKTRNoch keine Bewertungen

- MODEL 2800: Horizontal Split-Case PumpsDocument28 pagesMODEL 2800: Horizontal Split-Case PumpsCarlos_MKTRNoch keine Bewertungen

- Weber - Manuale OperativoDocument50 pagesWeber - Manuale OperativoFrancesco Marzari ChiesaNoch keine Bewertungen

- RT770E-Product-Guide-Imperial - 65t Mobile Crane Load ChartDocument20 pagesRT770E-Product-Guide-Imperial - 65t Mobile Crane Load ChartJay R Fuenzalida ValerosoNoch keine Bewertungen

- Installation, Start-Up and Service Instructions: 50HJ006-014 Single-Package Rooftop Cooling Units 50 HZDocument52 pagesInstallation, Start-Up and Service Instructions: 50HJ006-014 Single-Package Rooftop Cooling Units 50 HZchaefaure4aNoch keine Bewertungen

- Operation and Maintenance Manual IC-35-2GDocument71 pagesOperation and Maintenance Manual IC-35-2GRAFAEL OLIVEIRANoch keine Bewertungen

- 4JH5EDocument2 pages4JH5EDeganchileNoch keine Bewertungen

- AM012KNTDCHDocument1 pageAM012KNTDCHLindsay Elescano MartinezNoch keine Bewertungen

- NISSAN CatalogDocument9 pagesNISSAN Catalogabdullah kozanNoch keine Bewertungen

- 12-Service Manual 12-Cylinder Engine (6 0 LTR 4-Valve BHT, BSB & BTE) MechanicsDocument257 pages12-Service Manual 12-Cylinder Engine (6 0 LTR 4-Valve BHT, BSB & BTE) MechanicsНиколай НиколовNoch keine Bewertungen

- Fault Codes: STO U AndriivDocument8 pagesFault Codes: STO U AndriivAtochkavNoch keine Bewertungen

- Twin Disc Marine Product GuideDocument45 pagesTwin Disc Marine Product GuidejubriantoNoch keine Bewertungen

- 3116 Truck Engine 2FR00001-UP (SEBP2484 - 24) - Documentación PDFDocument12 pages3116 Truck Engine 2FR00001-UP (SEBP2484 - 24) - Documentación PDFAntony B. Bardales100% (2)

- Global Series - OMM-60HzDocument82 pagesGlobal Series - OMM-60HzLocacao Ar BrasilNoch keine Bewertungen

- 07 Exhaust Gas Recirculation (EGR) SystemDocument13 pages07 Exhaust Gas Recirculation (EGR) SystemMusaHamzicNoch keine Bewertungen

- Clark SM 575 Service ManualDocument20 pagesClark SM 575 Service Manualgerardo100% (59)

- Centek Keywords: Keywords We Get Traffic FromDocument8 pagesCentek Keywords: Keywords We Get Traffic FromRobbyNoch keine Bewertungen

- Double Acting Air CylinderDocument1 pageDouble Acting Air CylinderMelanie SamsonaNoch keine Bewertungen

- Mechatronics (MDB 4022) Project Guidelines: Xw2Pf4W7Mes7Lenw - QHPH - D - Jwrcja/Edit?Usp SharingDocument4 pagesMechatronics (MDB 4022) Project Guidelines: Xw2Pf4W7Mes7Lenw - QHPH - D - Jwrcja/Edit?Usp SharingCiro FerrariNoch keine Bewertungen

- Simple Machines WorkbookDocument23 pagesSimple Machines WorkbookGeniva TiroNoch keine Bewertungen

- Cambio Bomba Agua BMW E39Document19 pagesCambio Bomba Agua BMW E39Jorge SepulvedaNoch keine Bewertungen

- Catalogo Chumaceras C-DODGE-S2000 PDFDocument56 pagesCatalogo Chumaceras C-DODGE-S2000 PDFCarlos Andres Arias LopezNoch keine Bewertungen

- Janome 1600PQCDocument23 pagesJanome 1600PQCMichele NordahlNoch keine Bewertungen

- Split Cycle Engine: M.Loganathan Mechanical EnggDocument19 pagesSplit Cycle Engine: M.Loganathan Mechanical EnggVignesh SekarNoch keine Bewertungen

- Komparasi Alat BeratDocument5 pagesKomparasi Alat BeratNaufal AdihartoNoch keine Bewertungen

- GoodmanAC PDFDocument69 pagesGoodmanAC PDFGrady SandersNoch keine Bewertungen