Professional Documents

Culture Documents

ETS - DAF Brochure

ETS - DAF Brochure

Uploaded by

Corso JessycaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ETS - DAF Brochure

ETS - DAF Brochure

Uploaded by

Corso JessycaCopyright:

Available Formats

D The DAF Process

D issolved air flotation (DAF) is a proven and effective physical/chemical technology for

treating a variety of industrial process and wastewater streams, including those from

food processors, laundry facilities, pulp and paper producers, and biological

wastewater treatment systems.

The ETS RT Series DAF systems are designed to remove suspended solids (TSS), biochemical

oxygen demand (BOD5), and oils and greases (O&G) from a wastewater stream. Contaminants

are removed through the use of a dissolved air-in-water solution produced by injecting air under

pressure into a recycle stream of clarified DAF effluent. This recycle stream is then combined and

mixed with incoming wastewater in an internal contact chamber where the dissolved air comes

out of solution in the form of very fine bubbles that attach to the contaminants. The bubbles and

contaminants rise to the surface and form a floating bed of material that is removed by a surface

skimmer into an internal hopper for further handling.

Concurrent, flight and chain top

skimmer system allows for

Timer-operated, variable- longer float residence residence

speed drive allows fine time, resulting in the driest

tuning of top skimmer materials possible

operation to match float

production

Oversized, adjustable

effluent weir rings provide

easy adjustment of water

level and prevents

fluctuations from flow surges

Compact, heavy-duty

design allows for simple

installation and easy

cleaning around the unit

Oversized float hopper

provides intermediate

storage of material for

transfer to disposal or

dewatering

Counter-current, flight and chain

bottom skimmer system provides for

the removal of settled solids without

bridging problems (optional auger

system available)

Why Use an RT Series DAF?

E TS developed the RT Series of packaged DAF

systems over fifteen years of basic research and

multiple installations in a variety of industries.

These systems provide basic features not found with

other DAF systems:

" Quality drive and pump components for long-term

reliability

" Multi-step quality control program

" Full construction and component warranties

" Complete start-up and training

" Eleven (11) different units to meet a variety of

" Process design assistance

applications and flow ranges (10 to 2,500 gpm)

" Skid-mounted design for ease of installation and " Expert technical support before and after installation

rapid start-up

" Rectangular profile for maximum space utilization

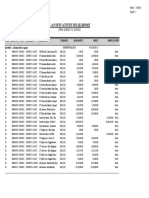

RT Series Specification Data

" Simple, effective controls and operation

DAF Surface Length Width Height

Model Area (ft2) (ft) (ft) (ft)

RT–15 14 9’-5” 3’-3” 5’-2”

Innovative contact chamber that

RT–30 31 11’-7” 5’-3” 6’-10”

features multiple recycle injection ports

and a mid-tank injection system to RT–50 57 13’-10” 7’-2” 7’-1”

improve bubble-to-contaminant contact.

An adjustable weir provides even flow RT–70 74 16’-10” 7’-2” 7’-1”

distribution through the unit RT–100 98 17’-6” 9’-4” 8’-1”

RT–140 143 23’-6” 9’-4” 8’-1”

RT–160 159 26’-6” 9’-4” 8’-1”

Recycle pressurization

and air supply RT–180 181 24’-7” 11’-3” 9’-8”

controls are RT–240 238 30’-7” 11’-3” 9’-8”

simple to use

RT–350 384 30’-6” 12’-4” 9’-8”

RT–500 480 47’-9” 12’-4” 9’-8”

HOW IS THE HELLBENDER© DAF PUMP DIFFERENT

FROM A REGULAR CENTRIFUGAL PUMP?

" Specially designed

High efficiency, air-in-water solution to operate at high

(whitewater) system, featuring the

(>100 psi) pressures

Hellbender© DAF Pump, to provide

true dissolved air with high and pump water with

concentrations of fine bubbles. entrained air without

cavitating

" Higher air dissolving efficiency vs. standard

Innovative air induction centrifugal pumps due to high pressure and

system produces unique design

dissolved air without a " Hellbender© DAF Pumps are distributed

compressed air supply

worldwide by ETS

Flocculation Systems

ETS provides high-efficiency Flocculation Systems for installation prior to DAF:

Flocculation Tubes

A simple, low-energy means of introducing coagulating and flocculating

chemicals into a waste stream prior to flotation. The systems feature

serpentined, corrosion resistant piping with non-clogging mixing zones for

optimum mixing of chemicals. The systems are mounted in heavy-duty,

galvanized steel frames for long service life.

Flash Mix and Flocculation Tank Systems

For applications that have more complicated chemistries, such as pH control,

ETS provides Flash Mix and Flocculation Tank Systems for the introduction of

coagulating and flocculating chemicals into a waste stream. The tanks are sized

to match the flow requirements of the DAF and come in FRP, HDPE, or 304SS

construction. The systems feature Hellbender© Mixers with heavy-duty drive

motors and stainless steel shafts and turbines.

Turn-Key Systems

ETS will provide DAF systems and related components either on a component basis or

as a complete turn-key installation. ETS process engineers will work with consulting

engineers or directly with a client to develop a treatment process and provide and

install all of the components necessary for a complete system. Turn-key systems have

the advantage of providing a client with a single source of supply and accountability.

Treatability Testing

ETS has a comprehensive laboratory testing program to evaluate a waste stream

for dissolved air flotation. Portable pilot systems are available to replicate actual

process conditions and provide detailed design and operational information for

use in the design of a full-scale pretreatment system.

About ETS

Environmental Treatment Systems, Inc. is a full-service environmental company that has been providing engineered

solutions to industrial wastewater problems since 1987. Other treatment systems from ETS include:

" Hellbender DAF Pumps

©

" ETSBR aerobic systems

©

" Hellbender Mixing Systems

©

" Polymer feed systems

" SepaFloat solids removals systems

©

" Sludge dewatering systems

" PABR anaerobic systems

©

" pH control systems

ETS is a

P. O. Box 94005 " Atlanta, Georgia USA 30377-1005 member of:

Phone: (770) 384-0602 " Fax: (770) 384-0603

E-mail: [email protected]

Website: ETSenvironmental.com

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5836)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (862)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (351)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (268)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- SOAS Syllabus - Preliminary Math CourseDocument2 pagesSOAS Syllabus - Preliminary Math CourseAlberto LucioNoch keine Bewertungen

- Report Writing Guidelines - CMIDocument5 pagesReport Writing Guidelines - CMIShivali RS SrivastavaNoch keine Bewertungen

- New Indy ComplaintDocument5 pagesNew Indy ComplaintEmma KoryntaNoch keine Bewertungen

- Problem Statement T1 2012-2013 (Selected Project 3)Document3 pagesProblem Statement T1 2012-2013 (Selected Project 3)Bejavada SureshNoch keine Bewertungen

- Demand Ventilation For KitchensDocument5 pagesDemand Ventilation For KitchensOscar Barón GaonaNoch keine Bewertungen

- Robotics QuizDocument1 pageRobotics QuizCary B. EscabarteNoch keine Bewertungen

- Claim Statement Form - Lender Borrower Group: Policy DetailsDocument1 pageClaim Statement Form - Lender Borrower Group: Policy DetailsShivNoch keine Bewertungen

- Error Detection CorrectionDocument49 pagesError Detection Correctionsiddhanta69Noch keine Bewertungen

- (ACI-336-2r - 88) - Suggested Analysis and Design Procedures For Combined Footings and MatsDocument21 pages(ACI-336-2r - 88) - Suggested Analysis and Design Procedures For Combined Footings and MatsCarlos Francisco Gutiérrez DavilaNoch keine Bewertungen

- Dental Dialogue 07 2011 ENDocument16 pagesDental Dialogue 07 2011 ENJames LinNoch keine Bewertungen

- 2020 Global Wibu ReportDocument26 pages2020 Global Wibu ReportCom DigfulNoch keine Bewertungen

- Marriage in Korea (USFK FN) 13MAR20Document4 pagesMarriage in Korea (USFK FN) 13MAR20cNoch keine Bewertungen

- 2017 Logan Lamb AffidavitDocument5 pages2017 Logan Lamb AffidavitPaul WallNoch keine Bewertungen

- 487 PosterDocument1 page487 PosterHARSH PAREKHNoch keine Bewertungen

- Quality CircleDocument7 pagesQuality CircleSwapnesh SharmaNoch keine Bewertungen

- What Is MotivationDocument10 pagesWhat Is MotivationSwarnajeet GaekwadNoch keine Bewertungen

- Secondary Storage MediaDocument4 pagesSecondary Storage MediaOumotiaNoch keine Bewertungen

- PDF Medical Sciences Naish Ebook Full ChapterDocument53 pagesPDF Medical Sciences Naish Ebook Full Chapterbernadette.rollins892100% (4)

- 2.310-Accident Investigation & Reporting1Document23 pages2.310-Accident Investigation & Reporting1kirandevi1981Noch keine Bewertungen

- PT Geoservices LTD.: FROM 01/08/2022 TO 31/08/2022Document6 pagesPT Geoservices LTD.: FROM 01/08/2022 TO 31/08/2022heruNoch keine Bewertungen

- Royal Thai Policing SystemDocument18 pagesRoyal Thai Policing SystemChristianJohn Nunag100% (1)

- Steps To Make A Contextualize ResearchDocument2 pagesSteps To Make A Contextualize ResearchJkrAin AteinroNoch keine Bewertungen

- Empcal 2443480Document3 pagesEmpcal 2443480Tajinder SinghNoch keine Bewertungen

- Space ProbeDocument12 pagesSpace Probeahmed youssefNoch keine Bewertungen

- CARS-PART-11-version-4.0 Aerial WorkDocument29 pagesCARS-PART-11-version-4.0 Aerial Workvalentino slijngardNoch keine Bewertungen

- K Nearest Neighbor (KNN)Document9 pagesK Nearest Neighbor (KNN)simransolanki003Noch keine Bewertungen

- 3-Emergency ProucedureDocument56 pages3-Emergency Proucedurerozhinhadi63Noch keine Bewertungen

- Indirect Fired Heater Training ModuleDocument25 pagesIndirect Fired Heater Training ModuleEdith100% (2)

- Service History - ProvidentFundDocument1 pageService History - ProvidentFundSwarup MondalNoch keine Bewertungen

- A Design Model of Transient Temperature Performance For A Green GreenhouseDocument23 pagesA Design Model of Transient Temperature Performance For A Green GreenhouseAlexandraOrtizRochaNoch keine Bewertungen