Qmot Qbl4208 Family: V1.03 2010-Nov-03

Qmot Qbl4208 Family: V1.03 2010-Nov-03

Uploaded by

etolockaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Qmot Qbl4208 Family: V1.03 2010-Nov-03

Qmot Qbl4208 Family: V1.03 2010-Nov-03

Uploaded by

etolockaCopyright:

Available Formats

QMot QBL4208 family

Manual

V1.03

2010-NOV-03

Trinamic Motion Control GmbH & Co. KG

Sternstraße 67

D – 20357 Hamburg, Germany

http://www.trinamic.com

QBL4208 Manual (V1.03 / 2010-NOV-03) 2

Table of Contents

1 Life support policy ....................................................................................................................................................... 3

2 Features........................................................................................................................................................................... 4

3 Order codes.................................................................................................................................................................... 5

4 Mechanical Dimensions .............................................................................................................................................. 6

4.1 Dimensions ........................................................................................................................................................... 6

4.2 Leadwire Configuration ..................................................................................................................................... 6

5 Torque figures ............................................................................................................................................................... 7

5.1 Motor QBL4208-41-04-006.................................................................................................................................. 7

5.2 Motor QBL4208-61-04-013.................................................................................................................................. 8

5.3 Motor QBL4208-81-04-019.................................................................................................................................. 9

5.4 Motor QBL4208-100-04-025 ............................................................................................................................. 10

6 Motor sizing ................................................................................................................................................................. 12

6.1 Peak torque requirement ................................................................................................................................ 12

6.2 RMS torque requirement ................................................................................................................................. 12

6.3 Motor velocity .................................................................................................................................................... 13

7 Revision history .......................................................................................................................................................... 14

7.1 Document revision ........................................................................................................................................... 14

List of Figures

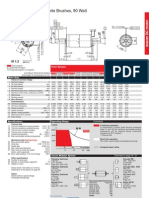

Figure 4.1: Dimensions (all values in mm) ................................................................................................................... 6

Figure 5.1: QBL4208-41-04-006 Velocity vs. Torque characteristics ......................................................................... 7

Figure 5.2: QBL4208-61-04-013 Velocity vs. torque characteristics .......................................................................... 8

Figure 5.3: QBL4208-81-04-019 Velocity vs. Torque characteristics ......................................................................... 9

Figure 5.4: QBL4208-100-04-025 Velocity vs. Torque characteristics ..................................................................... 10

Figure 5.5: QBL4208-100-04-025 Torque vs. Current characteristics ...................................................................... 11

Figure 6.1: Trapezoidal move and triangular move .................................................................................................. 13

List of Tables

Table 1.1: Motor technical data ......................................................................................................................................... 4

Table 3.1: Order codes ......................................................................................................................................................... 5

Table 4.1: Leadwire configuration .................................................................................................................................... 6

Table 7.1: Document revision .......................................................................................................................................... 14

Copyright © 2010, TRINAMIC Motion Control GmbH & Co. KG

QBL4208 Manual (V1.03 / 2010-NOV-03) 3

1 Life support policy

TRINAMIC Motion Control GmbH & Co. KG does not

authorize or warrant any of its products for use in life

support systems, without the specific written consent

of TRINAMIC Motion Control GmbH & Co. KG.

Life support systems are equipment intended to

support or sustain life, and whose failure to perform,

when properly used in accordance with instructions

provided, can be reasonably expected to result in

personal injury or death.

© TRINAMIC Motion Control GmbH & Co. KG 2010

Information given in this data sheet is believed to be

accurate and reliable. However neither responsibility

is assumed for the consequences of its use nor for

any infringement of patents or other rights of third

parties, which may result from its use.

Specifications are subject to change without notice.

Copyright © 2010, TRINAMIC Motion Control GmbH & Co. KG

QBL4208 Manual (V1.03 / 2010-NOV-03) 4

2 Features

QMOT BLDC motors are quality motors for universal use. They feature a long life due to ball bearings

and no wearing out parts. These BLDC motors give a good fit to the TRINAMIC family of medium and

high current BLDC motor modules.

Main characteristics:

Hall Effect Angle: 120° electric angle

Shaft run out: 0,025 mm

Insulation Class: B

Radial Play: 0,02 mm 450G load

Max Radial Force: 28N (10mm from flange)

Max Axial Force: 10N

Dielectric Strength: 500 VDC For One Minute

Insulation Resistance: 100M Ohm min. 500VDC

Recommended Ambient Temp.: -20 to +40°C

Bearing: Brushless motors fitted with ball bearings

QBL 4208

Specifications

-41-04-006 -61-04-013 -81-04-019 -100-04-025

No. of Pole 8 8 8 8

No. of Phase 3 3 3 3

Rated Voltage V 24 24 24 24

Rated Phase Current A 1.79 3.47 5.14 6.95

Rated Speed RPM 4000 4000 4000 4000

Rated Torque Nm 0.0625 0.125 0.185 0.25

Max Peak Torque Nm 0.19 0.38 0.56 0.75

Torque Constant Nm/A 0.035 0.036 0.036 0.036

Line to Line Resistance Ohm 1.8 0.72 0.55 0.28

Line to Line Inductance mH 2.6 1.2 0.8 0.54

Max Peak Current A 5.4 10.6 15.5 20

Length (LMAX) mm 41 61 81 100

Rotor Inertia kgm² x 10-6 24 48 72 96

Mass kg 0.3 0.45 0.65 0.8

Table 2.1: Motor technical data

Copyright © 2010, TRINAMIC Motion Control GmbH & Co. KG

QBL4208 Manual (V1.03 / 2010-NOV-03) 5

3 Order codes

Order code Description Dimensions (mm)

QBL4208-41-04-006 QMot BLDC motor 42 mm, 4000RPM, 0.06Nm 42 x 42 x 41

QBL4208-61-04-013 QMot BLDC motor 42 mm, 4000RPM, 0.13Nm 42 x 42 x 61

QBL4208-81-04-019 QMot BLDC motor 42 mm, 4000RPM, 0.19Nm 42 x 42 x 81

QBL4208-100-04-025 QMot BLDC motor 42 mm, 4000RPM, 0.25Nm 42 x 42 x 100

Table 3.1: Order codes

Copyright © 2010, TRINAMIC Motion Control GmbH & Co. KG

QBL4208 Manual (V1.03 / 2010-NOV-03) 6

4 Mechanical dimensions

4.1 Dimensions

22±1 Length 42

4xM4

45°

Ø5 42 42

3

400±20

Ø25.1

Ø36±0.1

Figure 4.1: Dimensions (all values in mm)

4.2 Leadwire configuration

Cable type 1 Gauge Function

Vcc Hall Sensor

Red UL1007 AWG26

+5VDC to +24VDC

Blue UL1007 AWG26 Hall A

Green UL1007 AWG26 Hall B

White UL1007 AWG26 Hall C

GND Hall

Black UL1007 AWG26

Sensor Ground

Yellow UL1007 AWG20 Phase U

Red UL1007 AWG20 Phase V

Black UL1007 AWG20 Phase W

Table 4.1: Leadwire configuration

Copyright © 2010, TRINAMIC Motion Control GmbH & Co. KG

QBL4208 Manual (V1.03 / 2010-NOV-03) 7

5 Torque figures

The torque figures detail motor torque characteristics measured in block commutation. Please be

careful not to operate the motors outside the blue field. This is possible for short times only because

of a resulting high coil temperature. The motors have insulation class B.

The blue field is described by rated speed and rated torque.

5.1 Motor QBL4208-41-04-006

Velocity vs. torque measured with 24V supply voltage

7000

6000

5000

4000

RPM

3000

2000

1000

0

0 0.02 0.04 0.06 0.08 0.1 0.12 0.14

N.m

Figure 5.1: QBL4208-41-04-006 velocity vs. torque characteristics

Copyright © 2010, TRINAMIC Motion Control GmbH & Co. KG

QBL4208 Manual (V1.03 / 2010-NOV-03) 8

5.2 Motor QBL4208-61-04-013

Velocity vs. torque measured with 24V supply voltage

7000

6000

5000

4000

RPM

3000

2000

1000

0

0 0.05 0.1 0.15 0.2 025 0.3

N.m

Figure 5.2: QBL4208-61-04-013 velocity vs. torque characteristics

Copyright © 2010, TRINAMIC Motion Control GmbH & Co. KG

QBL4208 Manual (V1.03 / 2010-NOV-03) 9

5.3 Motor QBL4208-81-04-019

Velocity vs. torque measured with 24V supply voltage

6000

5000

4000

RPM

3000

2000

1000

0

0 0.05 0.1 0.15 0.2 0.25 0.3

N.m

Figure 5.3: QBL4208-81-04-019 velocity vs. torque characteristics

Copyright © 2010, TRINAMIC Motion Control GmbH & Co. KG

QBL4208 Manual (V1.03 / 2010-NOV-03) 10

5.4 Motor QBL4208-100-04-025

Velocity vs. torque measured with 24V supply voltage

7000

6000

5000

4000

RPM

3000

2000

1000

0

0 0.05 0.1 0.15 0.2 025 0.3

N.m

Figure 5.4: QBL4208-100-04-025 velocity vs. torque characteristics

Copyright © 2010, TRINAMIC Motion Control GmbH & Co. KG

QBL4208 Manual (V1.03 / 2010-NOV-03) 11

Torque vs. current measured with 24V supply voltage

4

RPM

0

0 0.05 0.1 0.15 0.2 025 0.3

N.m

Figure 5.5: QBL4208-100-04-025 torque vs. current characteristics

Copyright © 2010, TRINAMIC Motion Control GmbH & Co. KG

QBL4208 Manual (V1.03 / 2010-NOV-03) 12

6 Motor sizing

For the optimum solution it is important to fit the motor to the application. The three key parameters

are peak torque requirement, RMS torque requirement and motor velocity.

6.1 Peak torque requirement

Peak torque TP is the sum of the torque due to acceleration of inertia (TI), load (TL) and friction (TF):

TP TJ TL TF

The torque due to inertia is the product of the load (including motor rotor) inertia and the load

acceleration:

TJ J a

The torque due to the load is defined by the configuration of the mechanical system coupled to the

motor. The system also determines the amount of torque required to overcome the friction.

6.2 RMS torque requirement

Root-Mean-Square or RMS torque is a value used to approximate the average continuous torque

requirement. Its statistical approximation is with

t1: acceleration time t2: run time t3: deceleration time t4: time in a move

TP2 t 1 TL TF t 2 TJ TL TF t 3

2 2

TRMS

t1 t 2 t 3 t 4

Copyright © 2010, TRINAMIC Motion Control GmbH & Co. KG

QBL4208 Manual (V1.03 / 2010-NOV-03) 13

6.3 Motor velocity

The motor velocity is also dictated by the configuration of the mechanical system that is coupled to

the motor shaft, and by the type of move that is to be affected. For example, a single velocity

application would require a motor with rated velocity equal to the average move velocity. A point to

point positioning would require a motor with a rated velocity higher than the average move velocity.

(The higher velocity would account for acceleration, deceleration and run times of the motion profile).

Figure 6.1: Trapezoidal move and triangular move relates rated motor velocity to average move

velocity for two point to point positioning move profiles.

Trapezoidal move Triangular move

Vmax

Vmax

(1/4)D (1/2)D (1/4)D

(1/2)D (1/2)D

t1 t2 t3 t4 t1 t3 t4

For acceleration portion of curve: For acceleration portion of curve:

For entire move: For entire move:

Example: Example:

ωmax rated operating speed of motor RPM

ωtrap average speed of motor required for a specified trapezoidal move, RPM

ωtri average speed of motor required for a specified triangular move, RPM

D total distance traveled, motor shaft revolutions

t1 acceleration time, seconds

t2 run time, seconds

t3 deceleration time, seconds

t4 dwell time, seconds

Figure 6.1: Trapezoidal move and triangular move

Copyright © 2010, TRINAMIC Motion Control GmbH & Co. KG

QBL4208 Manual (V1.03 / 2010-NOV-03) 14

7 Revision history

7.1 Document revision

Version Date Author Description

1.00 2007-MAY-09 HC Initial Release

1.01 2008-APR-01 GE Motor coil connections corrected

1.02 2008-NOV-25 MJ Leadwire corrected

1.03 2010-NOV-03 SD New motor drawings, order codes added, minor changes

Table 7.1: Document revision

Copyright © 2010, TRINAMIC Motion Control GmbH & Co. KG

You might also like

- Autoclave Instruction ManualDocument66 pagesAutoclave Instruction Manualwameath67% (3)

- Manual Do Reparador 8FBMT40-45-50Document702 pagesManual Do Reparador 8FBMT40-45-50Vitor Hugo100% (5)

- Caterpillar Generator Data C15Document12 pagesCaterpillar Generator Data C15Aditya PratamaNoch keine Bewertungen

- Qmot Qsh6018 ManualDocument14 pagesQmot Qsh6018 ManualleftoverchopsNoch keine Bewertungen

- Caterpillar Generator Data SR4Document7 pagesCaterpillar Generator Data SR4hector gutierrez100% (1)

- ALBRY10021H00AA InstDocument10 pagesALBRY10021H00AA InstMarcus TornovskyNoch keine Bewertungen

- BLM Datasheet PDFDocument4 pagesBLM Datasheet PDFMunja KlanaNoch keine Bewertungen

- Index: Chapter One System DescriptionDocument25 pagesIndex: Chapter One System DescriptionTristan MarcelNoch keine Bewertungen

- Specifications: 14M and 16M Motor Graders Power TrainDocument40 pagesSpecifications: 14M and 16M Motor Graders Power Trainwilly1234512Noch keine Bewertungen

- Alternator Caterpillar SR5 1868 Specificatie Tehnica ENDocument8 pagesAlternator Caterpillar SR5 1868 Specificatie Tehnica ENLiviu PetreusNoch keine Bewertungen

- m9447 PipDocument7 pagesm9447 PipalexastuvilcaNoch keine Bewertungen

- En 22 129Document1 pageEn 22 129Best of BestNoch keine Bewertungen

- 6-7 Ecc Machine Card c20913-16223cnDocument2 pages6-7 Ecc Machine Card c20913-16223cnAbas AbasariNoch keine Bewertungen

- Model 851 Mark-2 Marine Radar Sme 34900a 58Document58 pagesModel 851 Mark-2 Marine Radar Sme 34900a 58gitlatsubNoch keine Bewertungen

- MSM Series Brushless Servo Motor Manual: © 2003 Sheffield Automation, LLC. All Rights ReservedDocument11 pagesMSM Series Brushless Servo Motor Manual: © 2003 Sheffield Automation, LLC. All Rights Reservedsppa1Noch keine Bewertungen

- Asanor Compact Iran 2 PDFDocument71 pagesAsanor Compact Iran 2 PDFSatisNoch keine Bewertungen

- Lexium 23 Plus - BCH0802O12A1CDocument4 pagesLexium 23 Plus - BCH0802O12A1Cagungch100% (1)

- CL57TDocument13 pagesCL57TPerco De los palotesNoch keine Bewertungen

- Caterpillar Generator DataDocument8 pagesCaterpillar Generator Dataigor.g.galanteNoch keine Bewertungen

- MCTD-520 User S ManualDocument16 pagesMCTD-520 User S ManualMiguel Lalangui DomíngezNoch keine Bewertungen

- Shalamcheh Old Alternator OnDocument16 pagesShalamcheh Old Alternator OnNihar RoyNoch keine Bewertungen

- RENR8341-04-00-T&A Hydraulic FanDocument32 pagesRENR8341-04-00-T&A Hydraulic FanJesus Antonio Salazar WaldronNoch keine Bewertungen

- Caterpillar Generator Data SR5Document7 pagesCaterpillar Generator Data SR5hector gutierrezNoch keine Bewertungen

- Especificação Válvula Saída Do ConversorDocument1 pageEspecificação Válvula Saída Do ConversorflavioNoch keine Bewertungen

- TPLCEDocument2 pagesTPLCEjohnta001Noch keine Bewertungen

- WWL - DC Brushless MotorDocument28 pagesWWL - DC Brushless MotorAdi SupriadiNoch keine Bewertungen

- v4555 PipDocument7 pagesv4555 Pipbdrepublicadominicana2020Noch keine Bewertungen

- SCX550E SM 1-2-1 For TNDocument35 pagesSCX550E SM 1-2-1 For TNilonk antonieNoch keine Bewertungen

- Motor 2.5 HP - ShakersDocument2 pagesMotor 2.5 HP - ShakersAlex SinissNoch keine Bewertungen

- HLV2005MK Operat - InstructDocument33 pagesHLV2005MK Operat - Instructtim kaminskyNoch keine Bewertungen

- HX500GII-on MK5G2PK01E 40Document25 pagesHX500GII-on MK5G2PK01E 40al221511243Noch keine Bewertungen

- Maxon RE35 Graphite Brushes 90wattDocument1 pageMaxon RE35 Graphite Brushes 90wattElectromateNoch keine Bewertungen

- 3 3081483 enDocument2 pages3 3081483 enikhwanemocontechNoch keine Bewertungen

- DRE CAT Stepper Motors CatalogueDocument4 pagesDRE CAT Stepper Motors CatalogueSendi Dika PrasendaNoch keine Bewertungen

- Alternator Data Sheet Allied Generator.Document14 pagesAlternator Data Sheet Allied Generator.muhammad nomanNoch keine Bewertungen

- Impreza Service ManualDocument95 pagesImpreza Service ManualTaxiarhis ZoubosNoch keine Bewertungen

- Vacon NX Brake Resistors User Manual DPD01573A UKDocument38 pagesVacon NX Brake Resistors User Manual DPD01573A UKTanuTiganuNoch keine Bewertungen

- Technical Specification OF Mitsubishi Basic Diesel Generator SetDocument12 pagesTechnical Specification OF Mitsubishi Basic Diesel Generator SetFalgon IslamNoch keine Bewertungen

- FasilityDocument5 pagesFasilityይቤዬ የጌታ ልጅNoch keine Bewertungen

- Avis-II Dc280 EngDocument240 pagesAvis-II Dc280 EngJose Antonio Curiel ElizondoNoch keine Bewertungen

- Hemera Datasheet (Edition 3.3)Document10 pagesHemera Datasheet (Edition 3.3)opicaNoch keine Bewertungen

- DS Linear Motors P02-23Sx80Document19 pagesDS Linear Motors P02-23Sx80Arturo GomezNoch keine Bewertungen

- Mot260 ManualDocument7 pagesMot260 Manualtuandtd2008Noch keine Bewertungen

- 1 Generator Data 1442000-0.8Document6 pages1 Generator Data 1442000-0.8Abel Edwin Ccoyccosi ChuraNoch keine Bewertungen

- QNET ROTPEN User ManualDocument26 pagesQNET ROTPEN User ManualSuryabhan SinghNoch keine Bewertungen

- 16 275 enDocument1 page16 275 enmawadNoch keine Bewertungen

- Motores Maxon 2017Document1 pageMotores Maxon 2017--Noch keine Bewertungen

- Caterpillar Generator Data Production DE550 GCDocument8 pagesCaterpillar Generator Data Production DE550 GCDedi MaryadiNoch keine Bewertungen

- Kenr8501 02 00 - Manuals Service Modules - SpecificationsDocument22 pagesKenr8501 02 00 - Manuals Service Modules - SpecificationsCarlos Palpan ReyesNoch keine Bewertungen

- BLDC Motor 6 MM: ECX SPEED 6 M BrushlessDocument1 pageBLDC Motor 6 MM: ECX SPEED 6 M Brushlesskishan kharelNoch keine Bewertungen

- CC Pump Manual Full OriginalDocument109 pagesCC Pump Manual Full OriginalKanphong.smNoch keine Bewertungen

- Generator Data (C32 Serie SXC02993)Document7 pagesGenerator Data (C32 Serie SXC02993)Giovani Ascencio Yañez FloresNoch keine Bewertungen

- 8414 NhuDocument10 pages8414 NhuAdemar FukeNoch keine Bewertungen

- 6bwr15 6bws15 6bws11-20 6bwc10-20 Repair Manual Cl3ws-RpDocument471 pages6bwr15 6bws15 6bws11-20 6bwc10-20 Repair Manual Cl3ws-RpFco NinhoNoch keine Bewertungen

- He390hh E51+auo T390XVN01 0 PDFDocument29 pagesHe390hh E51+auo T390XVN01 0 PDFLeudin Russo PedrozaNoch keine Bewertungen

- CLAA102NA0ACWDocument16 pagesCLAA102NA0ACWIvan BenginNoch keine Bewertungen

- Generator DataDocument8 pagesGenerator Dataramirex_umsaNoch keine Bewertungen

- Direct Drive Servomotor Turrets: SeriesDocument18 pagesDirect Drive Servomotor Turrets: SeriesSHG AUTMEC MANUTENÇÃO E AUTOMAÇÃO MÁQ. INDUSTRIAISNoch keine Bewertungen

- Dynamometer: Theory and Application to Engine TestingFrom EverandDynamometer: Theory and Application to Engine TestingNoch keine Bewertungen

- Flexible Power Transmission: The HVDC OptionsFrom EverandFlexible Power Transmission: The HVDC OptionsRating: 5 out of 5 stars5/5 (1)

- Sample 100 ProblemsDocument7 pagesSample 100 ProblemsArgiel John LlagasNoch keine Bewertungen

- File 5e87d864ecef7Document15 pagesFile 5e87d864ecef7Amazonas ManutençãoNoch keine Bewertungen

- Lecture Week 6 PDFDocument43 pagesLecture Week 6 PDFfNoch keine Bewertungen

- ASCE003c11 p109-118 PDFDocument10 pagesASCE003c11 p109-118 PDFdbrooksuttNoch keine Bewertungen

- Undamped Free VibrationDocument7 pagesUndamped Free VibrationMD Atiqur Rahman Faisal100% (2)

- Basic Engineering For Medics and Biologists PDFDocument378 pagesBasic Engineering For Medics and Biologists PDFsadig babikerNoch keine Bewertungen

- Objective Questions in Engineering MechanicsDocument6 pagesObjective Questions in Engineering MechanicsrajkumardotcomNoch keine Bewertungen

- Lecture 36 - Lacing SystemsDocument16 pagesLecture 36 - Lacing SystemsGajendra JoshiNoch keine Bewertungen

- 3.DME - ME3RD - UNIT-3.2 - Design of JointsDocument70 pages3.DME - ME3RD - UNIT-3.2 - Design of JointsCHITYALA YASHWANTH KRISHNA ,ECE18 Vel Tech, ChennaiNoch keine Bewertungen

- Chapter 04 HomeworkDocument32 pagesChapter 04 HomeworkFatboy9181% (16)

- Tutorial 2Document3 pagesTutorial 2rafidah mazlanNoch keine Bewertungen

- Introduction To Earthquake Resistant StructuresDocument28 pagesIntroduction To Earthquake Resistant Structuressalmantop10% (1)

- Design of Flexural MembersDocument11 pagesDesign of Flexural Membersnoriebel OlivaNoch keine Bewertungen

- Graph Void Ratio Vs Effective StressDocument6 pagesGraph Void Ratio Vs Effective StressNitrogenn GassNoch keine Bewertungen

- 4-1 Video Lecture On Experimental Stress Analysis by Prof. K. Ramesh, IIT MadrasDocument32 pages4-1 Video Lecture On Experimental Stress Analysis by Prof. K. Ramesh, IIT MadrasarravindNoch keine Bewertungen

- hw1 PDFDocument2 pageshw1 PDFJungHyunParkNoch keine Bewertungen

- WEEK 9-Beban Terbagi RataDocument13 pagesWEEK 9-Beban Terbagi RataYayang MultazamNoch keine Bewertungen

- Expansion Loop Calculation: IndexDocument63 pagesExpansion Loop Calculation: Indexpjm0205Noch keine Bewertungen

- 5958r09-Earthquake Resistant Design of BuildingsDocument2 pages5958r09-Earthquake Resistant Design of BuildingsSagarNoch keine Bewertungen

- Spread Footing Verification Input Data: Ef Ef 3 Su 3Document8 pagesSpread Footing Verification Input Data: Ef Ef 3 Su 3asrdjanovNoch keine Bewertungen

- Leroueil Et Al-Compressibility of Sensitive Clays-Geotechnique-1985 PDFDocument22 pagesLeroueil Et Al-Compressibility of Sensitive Clays-Geotechnique-1985 PDFAngelica ZambranoNoch keine Bewertungen

- Engineering Materials and Their Properties: Jayant JainDocument18 pagesEngineering Materials and Their Properties: Jayant JainSatyaprakash KanaujiyaNoch keine Bewertungen

- Historia de Kerr Sobre Las Coordenadas de Kerr-SchildDocument36 pagesHistoria de Kerr Sobre Las Coordenadas de Kerr-SchildG. AlfredNoch keine Bewertungen

- SG Rule of Thumb For RC DesignDocument13 pagesSG Rule of Thumb For RC DesignRsjBugtongNoch keine Bewertungen

- Determining Angles in Shapes 2Document20 pagesDetermining Angles in Shapes 2Eduardo SilvaNoch keine Bewertungen

- ME478 FEA Su08 Syllabus PDFDocument2 pagesME478 FEA Su08 Syllabus PDFNurrohman NurrohmanNoch keine Bewertungen

- Linkage Lazy TongsDocument6 pagesLinkage Lazy TongsDodong AkoNoch keine Bewertungen

- Case Study (Closed Loop Thermal System)Document36 pagesCase Study (Closed Loop Thermal System)Anaya KhanNoch keine Bewertungen

- Lecture 12 - ME 243 - Beam DeflectionsDocument40 pagesLecture 12 - ME 243 - Beam Deflectionssalmanalamj5Noch keine Bewertungen